Linden Innovator

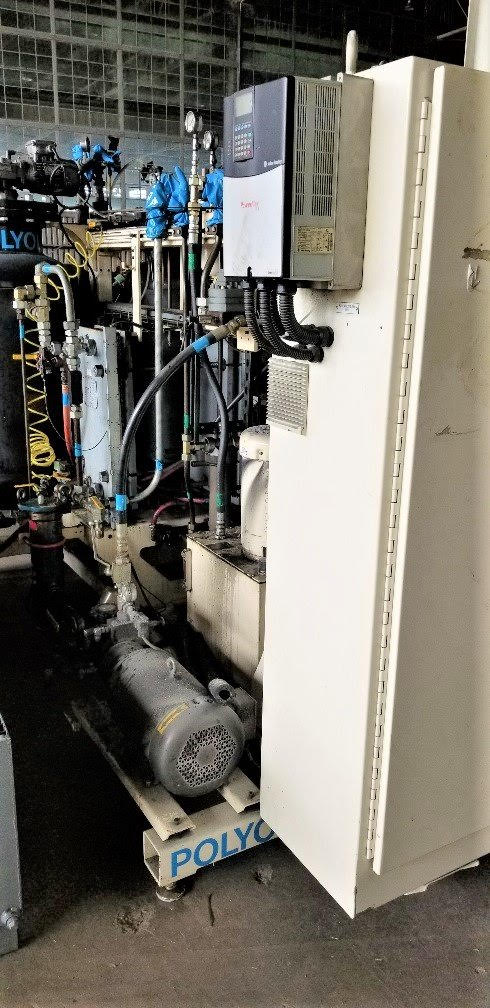

One (1) Linden INNOVATOR™ LPM 11/1750, S/N 09737A. The Machine was professionally cleaned out with DINP prior to shut down. This is a high end Linden machine. The modular design delivers good flexibility, allowing for many different configurations and production environments including interfacing to molding conveyors, turntables or stationary mold clamps.. The open frame design allows for ease of maintenance of componentry.

The system is capable of accurately controlling temperatures, meter, mix and dispense 2 component, unfilled reactive chemical systems at high pressures. Output range of the model LPM 11/1750 is from 128 to 642 grams per second with metering accuracy up to +/- 0.5 percent and impingement pressures up to 2800 PSI mixing pressure, based on 1.0 S.G at a 1:1 ratio.

The machine will be cleaned and painted in areas to make it cosmetically appealing. It will be completely gone thru to bring it up to original OEM output specifications, and ran off at our facility prior to sign off and shipping. You are welcome to come to the shop for that day and observe.

Machine Features

· 60 gallon Day Tanks, machine mounted, ASME rated to 110 PSI (10 bar)

· Tank Insulation

· Tank level indication (GEMS), with fill start set points

· Tank blanket pressure control and relief valve

· Fine Mesh Strainers for pump protection

· Rotary Power axial piston metering pumps

· Magnetically coupled Iso metering pump

· Variable ratios 1:5 to 5:1 (with identical size pumps on both components)

· Flow Meters VSE brand

· Flow / Ratio monitoring with deviation alarms

· L-Style mix head. New 8-12 size

· Shot size control based on time

· High efficiency plate and frame heat exchangers for temperature control accuracy

· Allen-Bradley PLC control – CompactLogix

· Proface HMI Large screen Model 3280024-02

· Allen Bradley Variable Frequency Drives - Powerflex

· Robot Pour Control signal interface - if required

· Last 10 Shot Data Collection

· Built-in electronic Mix Head Shot Counter

· 480v/3ph/60Hz

· High Pressure Select Valves for Energy Savings

· Calibration through Mix Head

· Return Line Drain Valves to simplify Chemical Changeovers or flushing chemicals from the machine

· Air Dryer

· Mix head boom, machine mounted, 6 or 10ft (1800-3000mm) radius, fixed height or 15in (380mm) adjustable lift w/ up - down pushbutton controls

{Type Your Site Name Here}

{Type a slogan for your site here}

Motor City Composites

Low Pressure Machines

High Pressure Machines

Lance Cylinder Machines

Hot Melt Machines

RIM Presses

Rexroth and Rotary Pumps

Mix Heads

Other RIM Items

Other Picked Items